The disappearance of engines inside wheels: A century-old technology poised to revolutionize electric mobility

The Resurgence of an Innovative Idea

At the beginning of the 20th century, when cars were still a novelty, Ferdinand Porsche introduced a vehicle that seemed ahead of its time: an electric carriage where each wheel had its own motor. The idea was simple and brilliant at the same time: to eliminate axles, differentials, and gears, allowing each wheel to function independently. Electricity was expensive, batteries were heavy, and the combustion engine had just become the new engineering god. Porsche’s proposal was relegated to a footnote in automotive history. Until now.

Efficiency and Power Combined

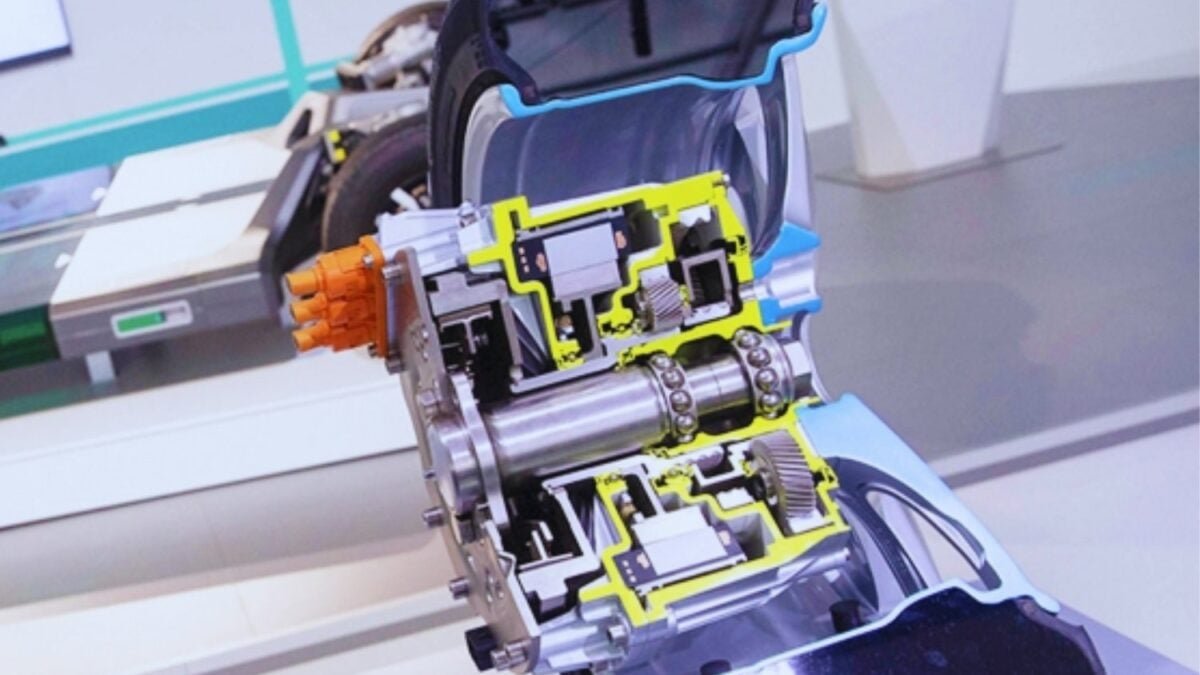

Over a century later, that same architecture—now known as an in-wheel motor or IWM—has made a strong comeback, driven by the electric revolution. Manufacturers like have perfected a concept that promises to completely change the way we understand electric cars: each wheel houses its own motor, inverter, and control system. With this arrangement, drive shafts, gearboxes, and differentials disappear, resulting in less mechanical losses and more energy efficiency. The numbers are impressive. The , designed for 18-inch wheels, can deliver up to 1,500 Nm of torque per wheel and surpass 300,000 kilometers without maintenance.

Overcoming Technical Challenges for a Brighter Future

Placing the motor inside the wheel poses a monumental technical challenge. Being so close to the ground, the motor must withstand impacts, water, vibrations, and constant heat. It also adds unsprung mass—weight that does not support the suspension—which could affect stability. But engineers have found solutions: active suspensions, ultra-light materials, and oil or liquid nitrogen cooling systems that keep the temperature under control. What was an impossible idea 100 years ago is now a tangible reality.

If manufacturers can reduce costs and overcome the latest thermal barriers, they could completely abandon centralized motors. The space freed up in the chassis could be used for more batteries, increased range, or safer impact absorption structures. In the words of Stephen Lambert, CTO of Protean: “The in-wheel motor not only redefines efficiency but also design. It is the next logical step in the evolution of the electric car.” Perhaps the future of automotive industry does not involve inventing something new, but in rescuing a brilliant idea from the past and finally giving it a new life.